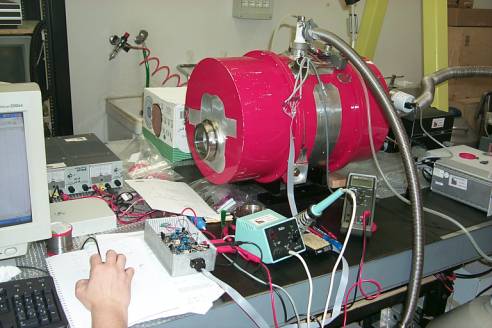

TEST of Steering mirror Prototype of KMOS at cryogenic temperature

The prototype inside the test dewar

After small adjustments of the electronic amplifier required because of the coil impedance variation due to the cryogenic conditions (305 Ohms at 25°C, against 42 Ohms at -195°C) and after the correction of PID values for stiffness variations, in Fig. 1 we show the first response of the system after the tuning process.

Figure 1: Response of X and Y axis at LN2 temperature

With the aim of measuring the steering mirror stability at LN2 temperature, we have performed a series of 1 hour continuous pointing tests. The standard deviation δ has been calculated for each min, max and middle pointing positions for each axis at position angles 0° and 90° with respect to gravity.

|

0° position relative to gravity |

Min Limit |

Middle |

Maximum |

|

X axis standard deviation |

0,21403717 |

0,26220851 |

0,26560665 |

|

Y axis standard deviation |

0,1811642 |

0,06863834 |

0,21514838 |

Table 1: Pointing stability (rms values) of both axes at 0° position

|

90° position relative to gravity |

Min Limit |

Middle |

Maximum |

|

X axis standard deviation |

0,44864406 |

0,36951023 |

0,44527012 |

|

Y axis standard deviation |

0,31750542 |

0,22992074 |

0,25045155 |

Table 2: Pointing stability (rms values) of both axes at 90° position

The standard deviations given in Table 1 and Table 2 correspond to fractions of 4.39", which is the present resolution given by the ADC. We can see that the stability of the system is around 2", which is almost a factor 2 better than the required 3.6".

To show the pointing position reliability for the steering mirror in cryogenic conditions, we have performed a 12 hour test continuously switching between two different pointing positions. As we can see from the images extracted from the sensor position collected data, there is no measurable difference between the response of the system at the beginning of the tests and after 12 hours