|

|

|

LabIR for GIANO

|

|

GIANO progresses in LabIR (Jan-Jun 06)

|

|

|

Bronze wheels for the filters holder, the slits holder and the

slit-pushing arm.

Each wheel is mounted on a specific support for the last

finishing.

|

|

Worm drives and relative bearings for the

stepper motors that control the

wheels movements.

|

|

|

|

We get some liquid nitrogen from Cryiomec refrigerator

|

|

It works! Some liquid nitrogen produced.

|

|

|

|

Wheel complex during lavoration.

|

|

Wheel complex during lavoration, rear view.

|

|

|

|

The helium compressor and the water filter.

|

|

The big air compressor.

|

|

|

|

The water refrigerator.

|

|

The laboratory arrangement.

|

|

|

|

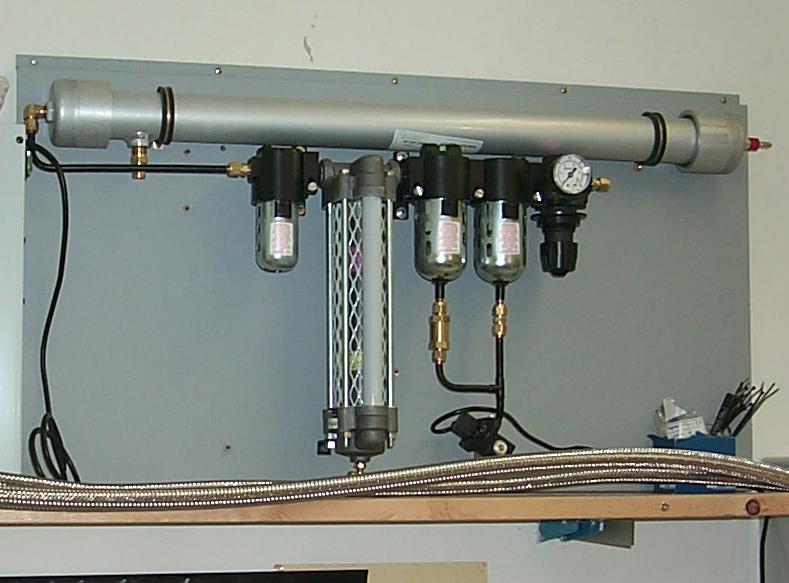

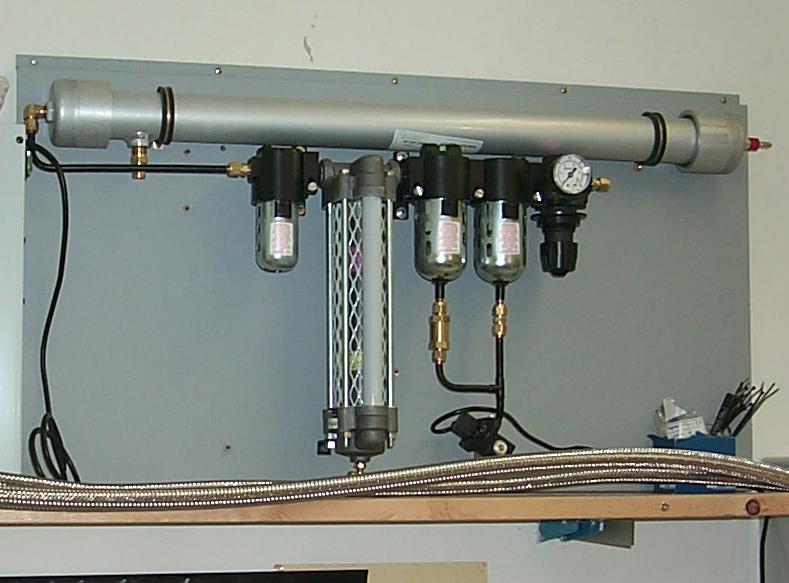

The nitrogen/oxigen filter

|

|

The liquid nitrogen dewar

|

|

|

|

An image of TMA1 Mirror

|

|

Self-portrait using TMA1 Mirror

|

|

|

|

The container arrives at Arcetri.

|

|

Planning of operations

|

|

|

|

Moving begins

|

|

The container in the final location

|

| Movies of container movement

1

2

3

|

|

|

|

Pressure in the new laboratory Dewar manifactured by Criotec.

|

|

Fit of pressure in Criotec Dewar with no pumping.

|

|

|

|

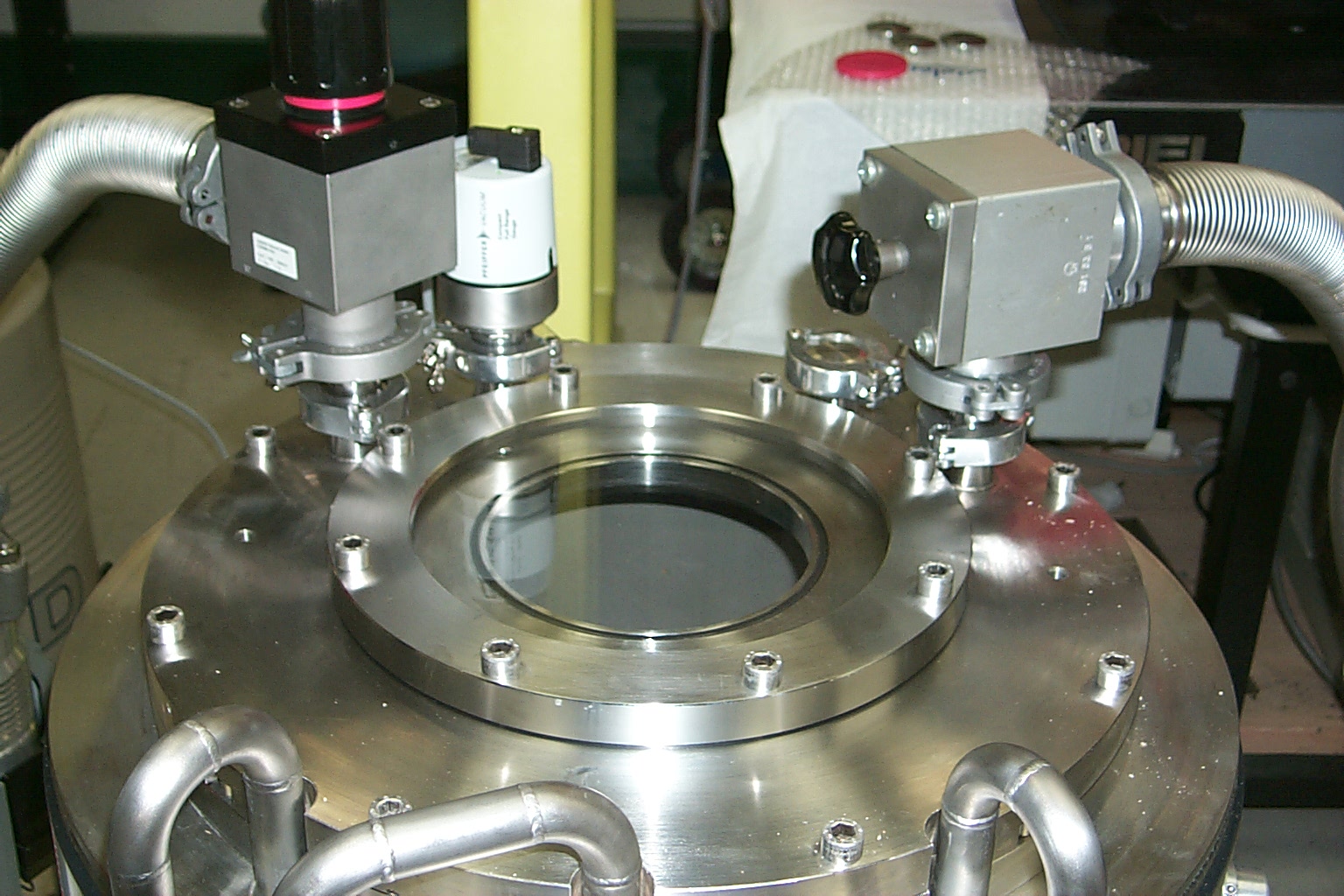

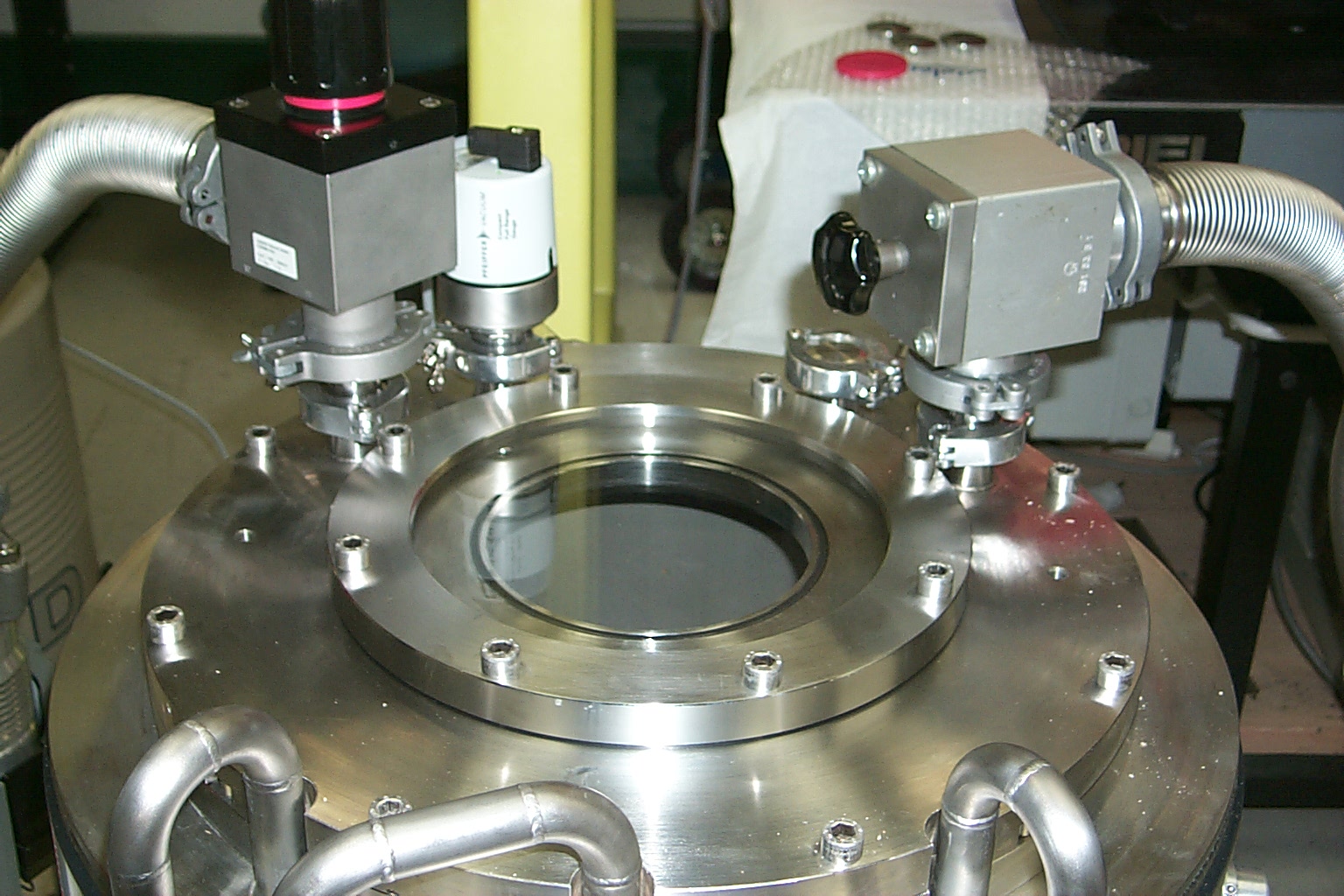

Test of the new laboratory Dewar manifactured by Criotec.

|

|

Details of vacuum pipes and of the huge entrance window.

|

|

|

|

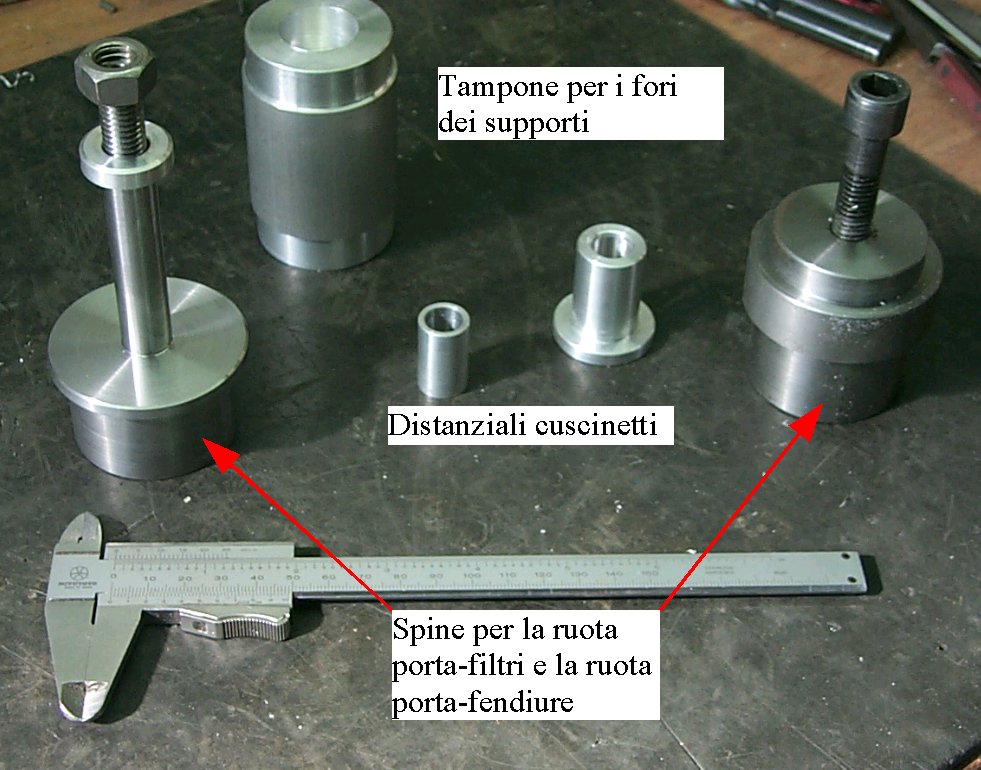

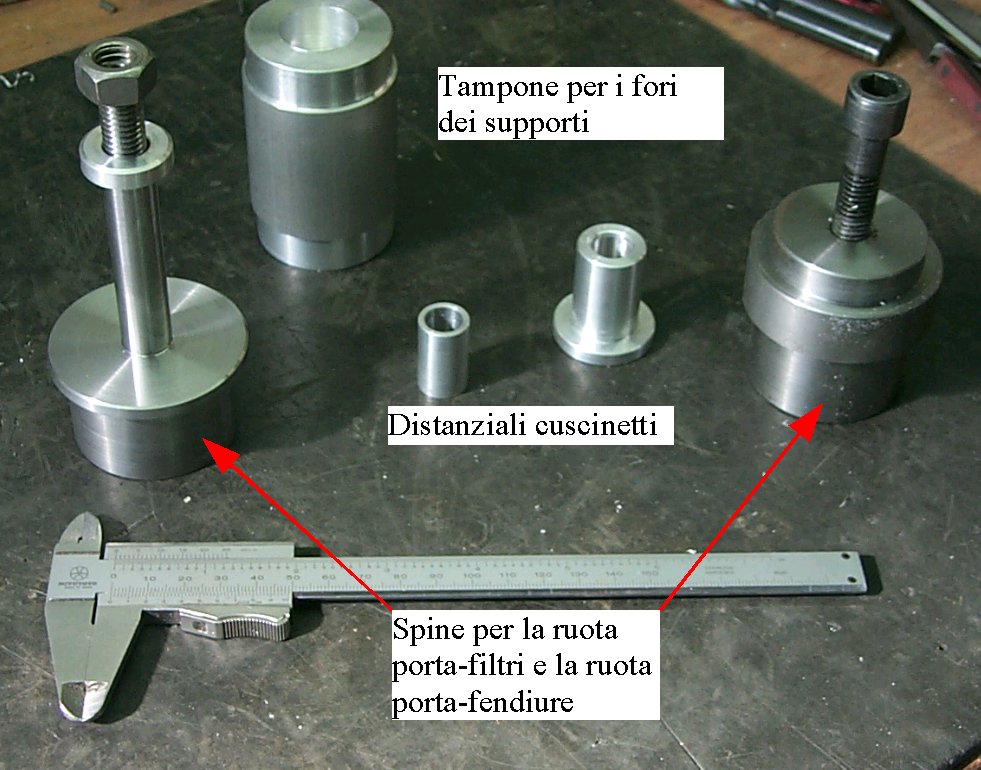

Mechanical tools manufactured for the realization of

the cryogenic

mechanics of GIANO.

|

|

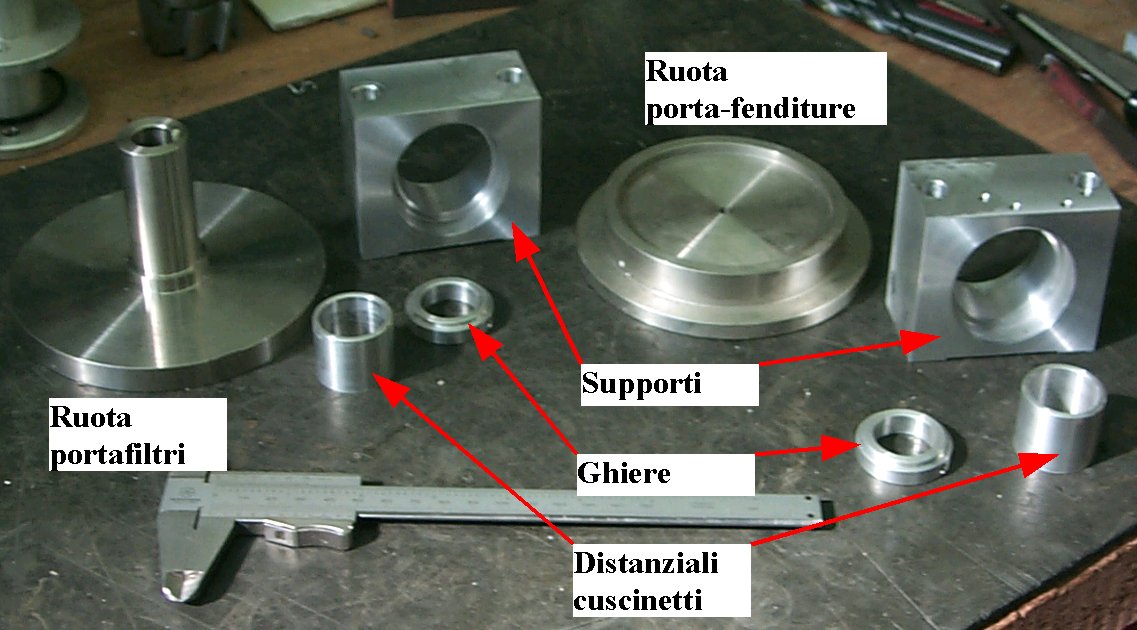

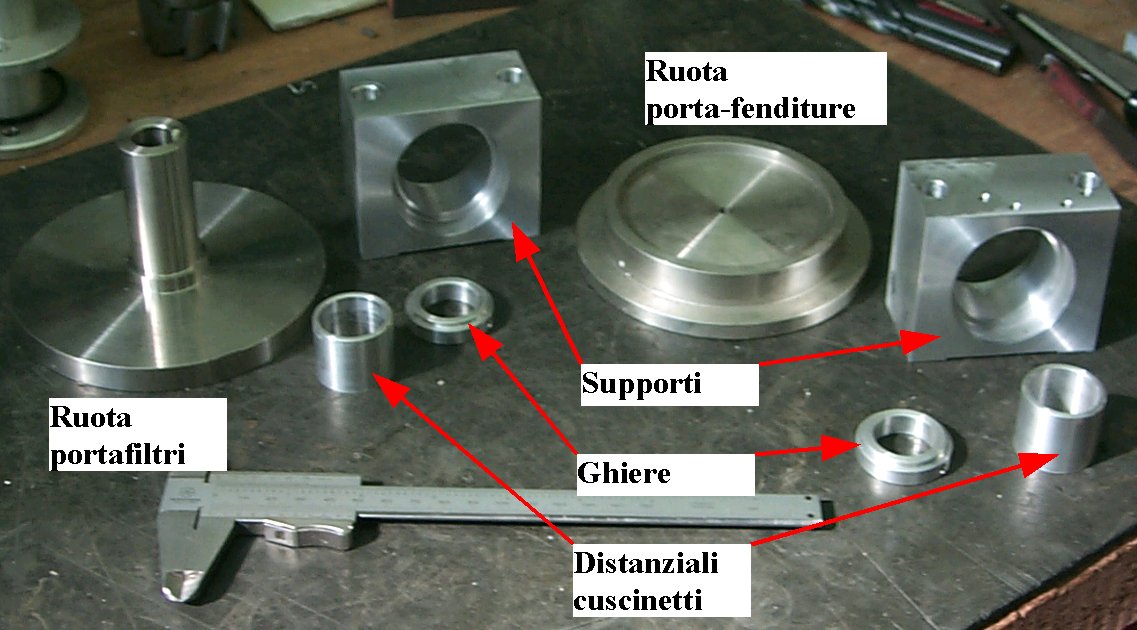

Various parts of the cryogenic mechanics of GIANO.

|

|

|

|

Measurement of the difference between the thermal expansion coefficients

of Al 6061 and Al 6082, by means of the deformation of a bimetallic strip.

|

|

Schema detailing the deformation computation.

|

|

|

|

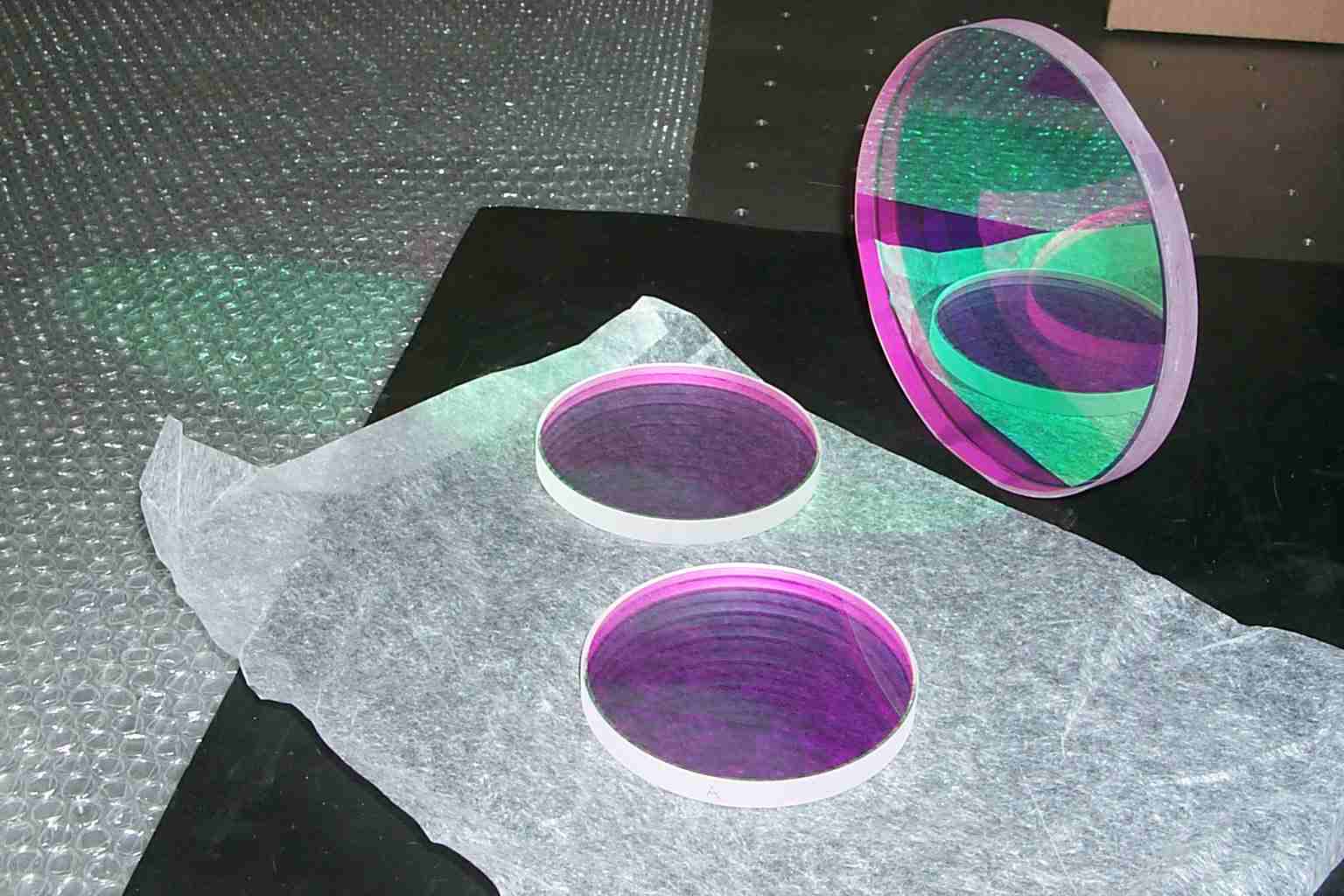

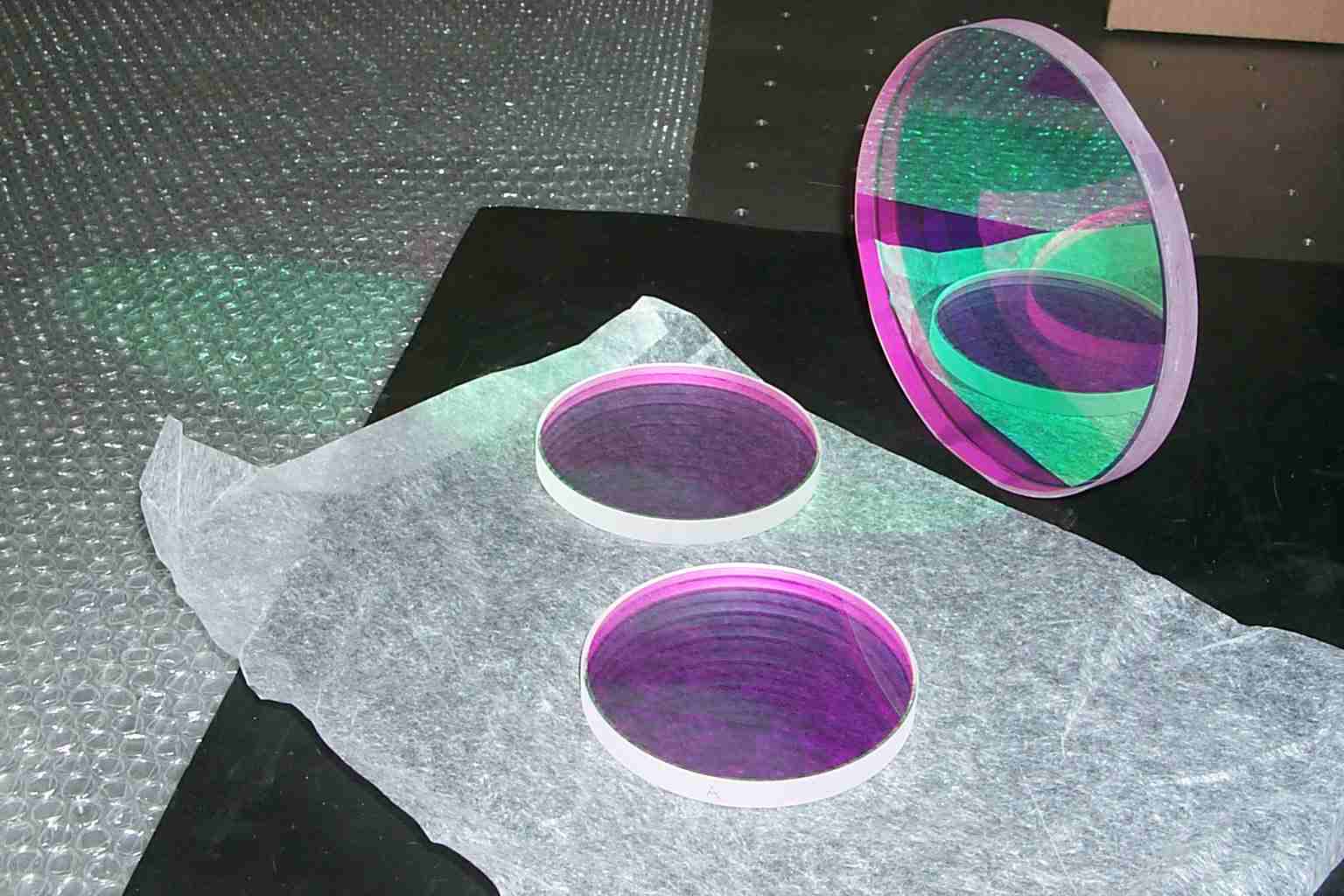

The ZnSe windows for the absorption cell.

|

|

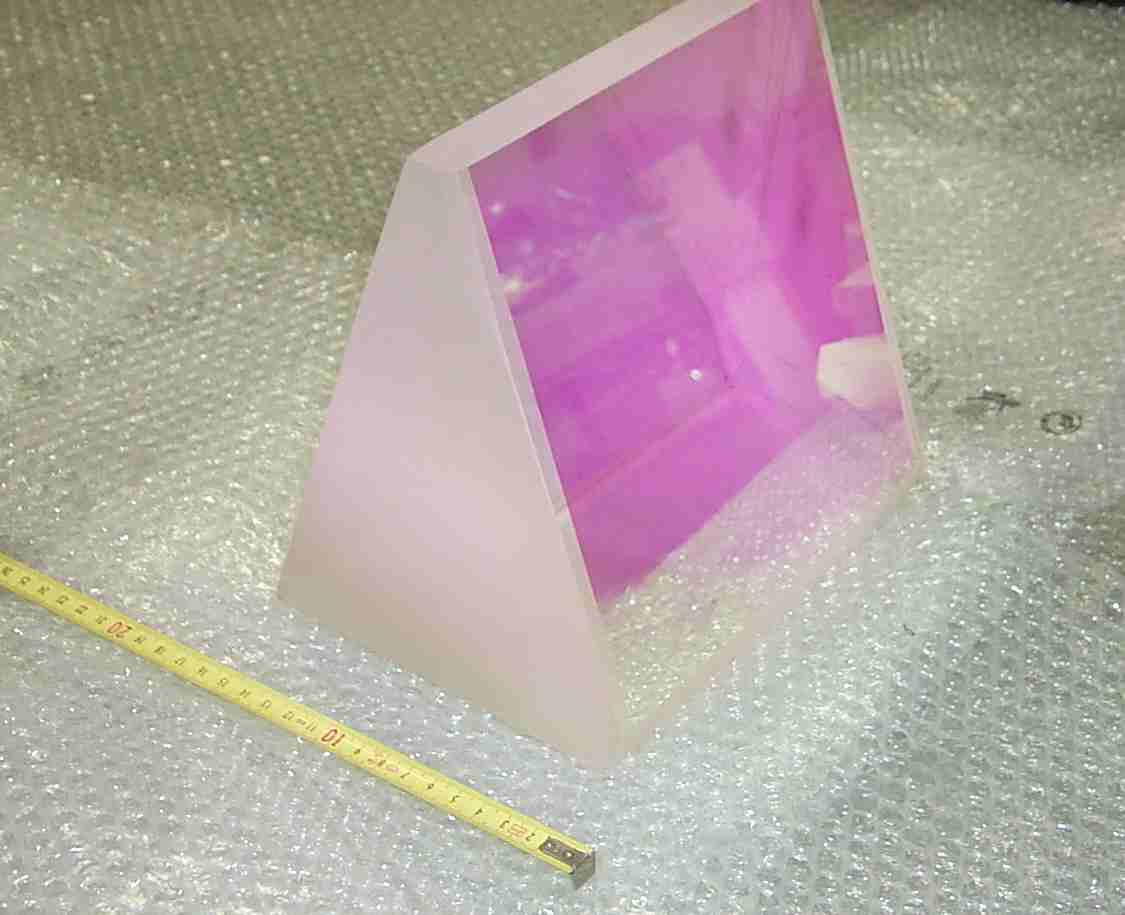

The big one is the Shifted High Resolution wedge and the smaller ones

are two fused silica windows with the same AR infrared coating.

|

|

|

|

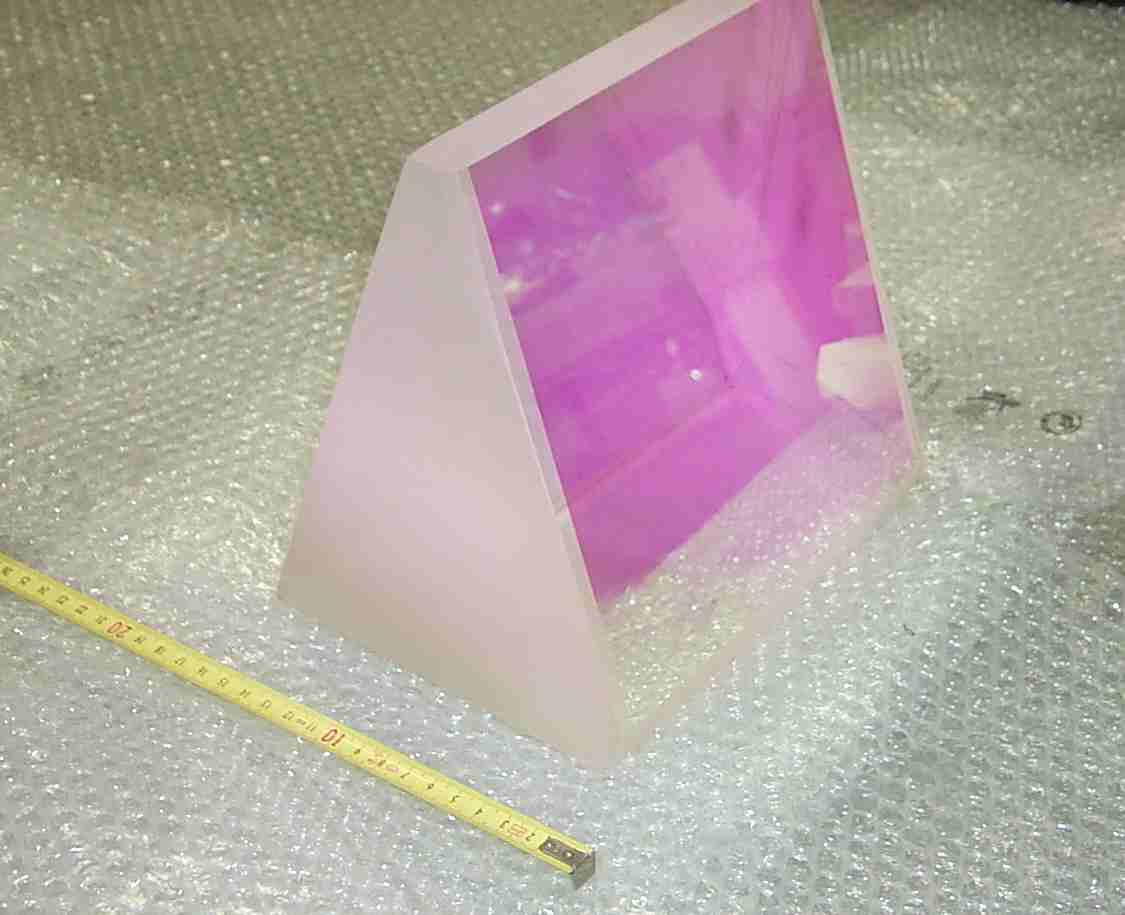

The detail of the base of GIANO infrasil prism. A chip was

removed before

the polishing to prevent further damage.

|

|

The huge infrasil prism of GIANO with IR anti-reflection coating.

|

|

GIANO Home Page

GIANO Home Page